- TURBOdesign Core

TURBOdesign Pumps & Fans

TURBOdesign Suite provides tools to designers to put them in direct control of aerodynamic design to streamline every step of the design process for turbomachinery components.

Our Pumps & Fans packages

- TURBOdesign Pro

TURBOdesign Compressors & Turbines

TURBOdesign Suite provides tools to designers to put them in direct control of aerodynamic design to streamline every step of the design process for turbomachinery components.

Our Compressors and Turbines packages...

- TURBOdesign Optima

TURBOdesign Optima

TURBOdesign Suite provides tools to designers to put them in direct control of aerodynamic design to streamline every step of the design process for turbomachinery components.

TURBOdesign Optima is our automatic optimization package

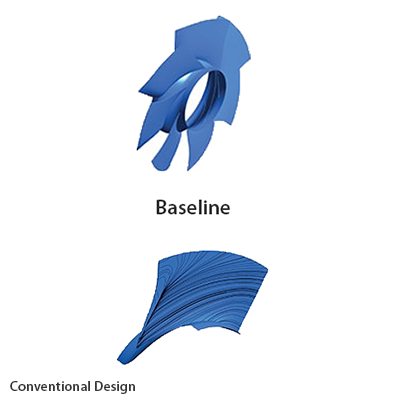

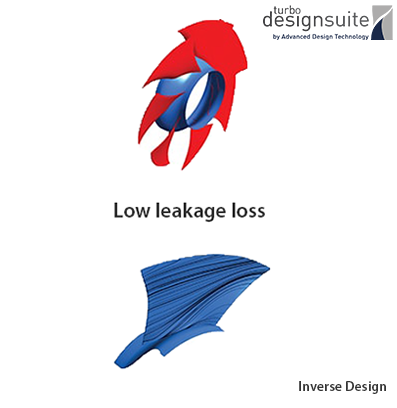

- Toolkit: 3D Blade Design

3D Blade Design

Our turbomachinery design toolkits include one on 3D blade design...

- Toolkit: Meanline Design

Meanline Design

TURBOdesign Suite provides tools to designers to put them in direct control of aerodynamic design to streamline every step of the design process for turbomachinery components.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Suspendisse varius enim in eros elementum tristique.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Suspendisse varius enim in eros elementum tristique. Duis cursus, mi quis viverra ornare, eros dolor interdum nulla, ut commodo diam libero vitae erat. Aenean faucibus nibh et justo cursus id rutrum lorem imperdiet. Nunc ut sem vitae risus tristique posuere.

- Toolkit: Volute / Scroll Geometries

Volute/Scroll Geometries

TURBOdesign Suite provides tools to designers to put them in direct control of aerodynamic design to streamline every step of the design process for turbomachinery components.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Suspendisse varius enim in eros elementum tristique. Duis cursus, mi quis viverra ornare, eros dolor interdum nulla, ut commodo diam libero vitae erat. Aenean faucibus nibh et justo cursus id rutrum lorem imperdiet. Nunc ut sem vitae risus tristique posuere.

- Toolkit: Multi-Point Optimization

Multi-Objective Optimization

TURBOdesign Suite provides tools to designers to put them in direct control of aerodynamic design to streamline every step of the design process for turbomachinery components.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Suspendisse varius enim in eros elementum tristique. Duis cursus, mi quis viverra ornare, eros dolor interdum nulla, ut commodo diam libero vitae erat. Aenean faucibus nibh et justo cursus id rutrum lorem imperdiet. Nunc ut sem vitae risus tristique posuere.

- Compressors and Turbines

Compressors

Test

- Fans and Blowers

Fans and Blowers

Test

- Pumps and Hydraulic Turbines

Pumps and Hydraulic Turbines

Test

- Transonic Compressors, Fans and Turbines

High Speed Turbines

Test

- Academia

Academia

Test

- Engineering Services

Design Consultancy

Test

- R & D

Research and Development

Test

- Training

Training

- Blog

Blog

Catch up with the very latest and useful articles

- Case Studies

Case Studies

Read our success stories from companies of all sizes who are transforming the way they design turbomachinery components.

- Consultancy Summaries

Consultancy Summaries

Read our success stories from companies of all sizes who are transforming the way they design turbomachinery components.

- Publications

Publication

Browse the latest and previous editions of our publications library

- Webinars

On-Demand Webinar Library

Playback our webinars

- White Papers

White Paper

Browse our white paper library.